Fire doors play a critical role in building safety, yet an often-overlooked issue in older buildings is how previous lock installations and replacements may have impacted their integrity. TLJ Access Control is working to raise awareness and provide a practical refurbishment solution to ensure fire doors maintain their intended performance.

The hidden threat behind the lock

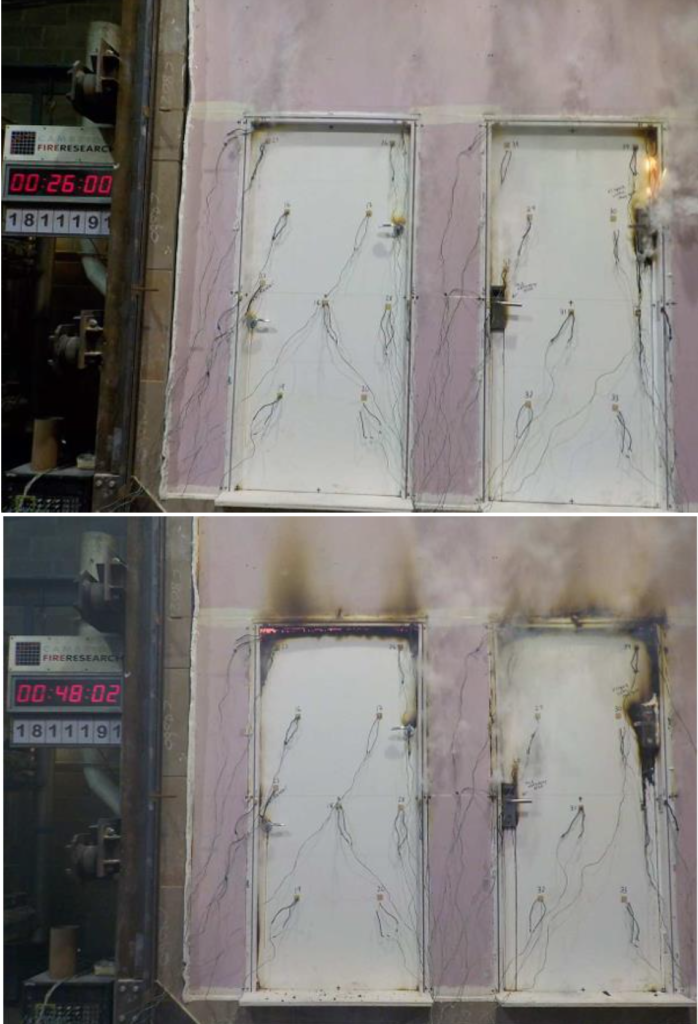

Recent burn tests conducted by TLJ at a UKAS accredited test laboratory have revealed alarming but vital findings about fire door integrity. For this test, TLJ used an existing fire door removed from a refurbishment project. The original lock and all apertures from past installations were left untouched to represent the door’s true in-use condition. Alongside this, on the same door but parallel, identical apertures were recreated, sealed using TLJ’s bespoke remediation solution, and one of TLJ’s electronic locks was installed – replicating exactly how the company would treat a door during refurbishment.

Within just 11 minutes of the burn test, significant smoke began to escape through the area surrounding the original lock – illustrating a real-world risk, since this door had been installed in a property in this exact state. By the 26 minute mark, flames had fully breached the compromised area and the fire had to be extinguished in that area to safely continue testing.

In stark contrast, the section of the same door restored with TLJ’s solution showed no signs of smoke or flame ingress for the full duration of the test. At 48 minutes, the test was manually terminated as flames began to pour through the top of the door (a natural outcome due to heat rising), yet no breach occurred through the TLJ-remediated lock area.

This 23 minute improvement in performance not only takes the door far beyond the 30 minute fire compliance standard, but it also nearly doubles the protection time of the original, compromised lock installation. That added time is critical – it increases the window for safe evacuation and helps contain the fire within a single room for significantly longer.

Despite this, the impact of unsealed apertures and poor lock retrofits is often overlooked during routine fire door inspections. TLJ is committed to raising awareness across the industry about the vital link between proper lock refurbishment and fire door integrity – because the right solution can save lives and dramatically extend the door’s effectiveness in an emergency.

Real world examples

Across multiple PBSA refurbishment projects, TLJ Access Control has identified a recurring issue: behind outdated or retrofitted locks, fire doors are often left with unsealed holes and poorly patched apertures. These legacy voids are sometimes hidden behind metal plates, behind or beside new locks, which poses a serious threat to fire performance and is frequently missed during standard visual inspections. While they may seem minor, such apertures can significantly reduce a door’s ability to contain a fire.

At each site, TLJ’s installation team conducted detailed assessments and used tailored remediation techniques to restore door integrity before fitting new electronic locks.

“In many cases, we found doors with multiple unsealed holes from previous installations – left completely untreated. It was eye-opening and highlighted the urgent need for proper remediation.”

TLJ Installation Team Lead, TLJ

Educating the industry: a call for action

The fire safety risk uncovered by TLJ is an issue that has long gone unnoticed by property owners, construction managers and even regulatory bodies. Without understanding what lies behind the electronic lock area of the door, compliance certifications may be issued without recognising the serious risk.

“Fire doors are a major component of the building’s fire safety strategy… I have served for over 26 years in the Fire Service both operationally as a firefighter and as a Senior Fire Safety Officer, I have witnessed first-hand how a “good” fire door operates and how a “poor” fire door operates and how that can have a detrimental effect on the safety and outcome of the people who occupy that building.

“TLJ have a solution that could improve integrity and performance of an existing fire door in a building… they believe in improving their knowledge and understanding of how their products fit into the built environment and developing the services they can provide moving forward.”

Ian Clarke, Compliance Manager, TLJ Access Control

TLJ is actively working with property managers and construction firms to spread awareness and implement solutions. The company is also gathering testimonials from industry professionals who have seen the benefits of TLJ’s approach firsthand.

Join the conversation

TLJ Access Control invites PBSA providers, fire compliance professionals and regulatory bodies to join the conversation, follow their LinkedIn and X accounts, and take a closer look at the hidden dangers that could be affecting thousands of buildings.

Sponsored content