Location: Confidential PBSA site, Midlands.

Sector: Purpose-built student accommodation (PBSA).

Operator: One of the UK’s leading student accommodation providers.

Scope: Fire door refurbishment and electronic lock retrofit.

Challenge: Restoring fire door integrity compromised by previous lock installations.

Overview

This case study focuses on a well-established PBSA development in the Midlands. When TLJ Access Control was brought in to retrofit new electronic locks, what initially appeared to be a straightforward upgrade quickly revealed deeper safety concerns. This project would go on to shape TLJ’s fire door remediation strategy and mark the launch of the TLJ Refurb solution.

The problem: legacy apertures and fire safety risk

Upon surveying the existing fire doors on this site, TLJ’s team discovered that large apertures had been cut into the doors to accommodate previous lock installations. These oversized voids had not been remediated, and installing new locks directly on top of them would have left gaping, unsealed holes, compromising the fire resistance of the doors.

While TLJ electronic locks required significantly smaller cut-outs, the damage left behind could not be ignored. Simply covering or ignoring these apertures would have dramatically reduced the door’s ability to contain a fire. Conscious of this safety risk, a tailored remediation solution was deemed necessary.

The solution: introducing the TLJ Refurb approach

This project marked the first PBSA refurbishment using what is now TLJ’s dedicated Refurb solution. The process involves assessing each door individually, sealing any unnecessary apertures using specialist fire-rated materials, and restoring the door’s structural integrity before installing a new lock.

These holes may seem minor, but they revealed a wider issue. Unsealed apertures can significantly reduce the fire resistance of a door – something that’s often not factored into visual compliance checks.

TLJ’s team conducted a careful assessment of each lock area. In cases where restoration was necessary, a tailored solution was applied using specialist materials to help return the door to a much higher level of integrity before any new locks were fitted.

“On this project, we realised that even a single previous installation can leave fire doors vulnerable if the apertures aren’t properly dealt with. I

“t wasn’t just about fitting our locks, it was about doing it responsibly and setting a new standard for safety in PBSA refurbishments.”

Nikki Ramskill, Project Manager, TLJ Access Control

The TLJ Refurb process offers a practical alternative to full door replacement in refurbishment projects whilst restoring doors to their original integrity and, in turn, restoring their compliance. It’s designed for live environments like PBSA and hospitality, where disruption must be kept to a minimum.

While TLJ does not issue fire door compliance certificates, the approach focuses on responsible restoration before any new access control system is installed.

The service includes:

- A detailed site survey carried out by ABBE Level 3 qualified fire door inspectors to review the fire door, including the area behind the lock.

- Tailored restoration based on door material and structure.

- Professional fitting of electronic locks once the lock area has been remediated, if necessary.

The work completed at this PBSA site is just one example of how legacy issues can be addressed during modern upgrades, with minimal disruption and maximum impact on safety, compliance and sustainability.

Fire test results: real-world evidence from PBSA

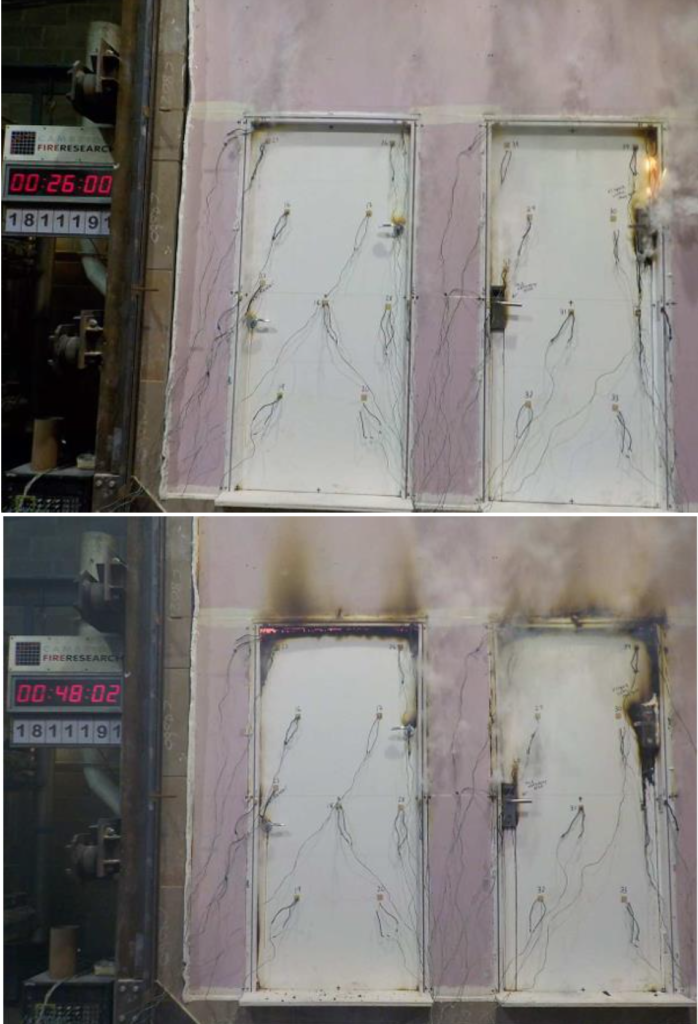

To prove the importance of proper remediation, TLJ conducted a full-scale fire door burn test at a UKAS-accredited test laboratory using an existing fire door removed from the project site.

- On the left-hand side of the door, the original lock area was refurbished using TLJ’s remediation materials and fitted with a TLJ electronic lock, replicating the Refurb solution as it would be implemented on-site.

- On the opposite side of the same door (parallel, on the same face), the original apertures were recreated and the old lock was re-installed to replicate the door’s previous, un-remediated condition.

Findings:

- 11 minutes: Smoke began leaking through the right-hand side with unsealed, original lock area.

- 25 minutes: Full flame breach through the compromised section (right-hand side), requiring extinguishment to continue the test.

- 48 minutes: No smoke or fire penetrated the TLJ-treated section (left-hand side). The test was terminated when flames began to breach the top of the door, due to heat rise, not through the lock area.

The Impact: Enhanced Protection & Industry Implications

This 23-minute performance improvement nearly doubles the protection time of the untreated door and goes well beyond the 30-minute fire compliance standard. That additional time is critical and provides greater opportunity for safe evacuation, gives emergency services a larger response window, and helps contain the fire within a single room for longer.

Despite this, visual fire door checks in refurbishment projects often overlook internal apertures, leaving serious vulnerabilities unaddressed.

Why it matters for PBSA

This was the first PBSA project to adopt the TLJ Refurb approach. However, the same issue had already been encountered in other sectors with older buildings, where a longer history of lock replacements had led to significant fire door degradation without proper remediation. Having seen the consequences firsthand and delivered solutions in those environments, TLJ recognised what needed to be done to prevent PBSA developments from following the same path as they begin to refurbish and upgrade their access control systems.

Without intervention, the very doors intended to protect student lives may become compromised by layers of poorly managed retrofits. TLJ chose not to be part of the problem – and instead created a solution to set a new safety standard for the future.

Conclusion

This project was more than a retrofit – it was a catalyst. It prompted TLJ to develop and formalise a new approach to fire door refurbishment, one that’s based on restoring integrity, not just replacing hardware.

By taking fire safety seriously and investing in remediation, TLJ is leading the way in protecting lives, extending door life cycles, and raising standards across the PBSA sector.

Sponsored content